4D Knit Dress

4D Knit Dress: Transforming Style

MIT Self-Assembly Lab x Ministry of Supply

MIT Self-Assembly Lab Team:

Sasha Mckinlay, Danny Griffin, Sofia Chen, Lavender Tessmer, Natalie Pearl, Susan Williams, Agnes Parker, Jared Laucks, Skylar Tibbits

Ministry of Supply Team:

Jarlath Mellett, Alessandra Vasi, Ryan Connary, Gihan Amarasiriwardena

Typical garment construction requires a designer to build a 2D pattern, then cut and sew from 2D fabric – yielding excess waste, additional cost/labor and bulky seams that don’t always follow human anatomy. New innovation in 3D knitting – akin to 3D printing - has allowed fabric variation and standardized 3D shaping - however customized shaping of knitted garments to fit anyone’s unique body or style hasn’t been possible.

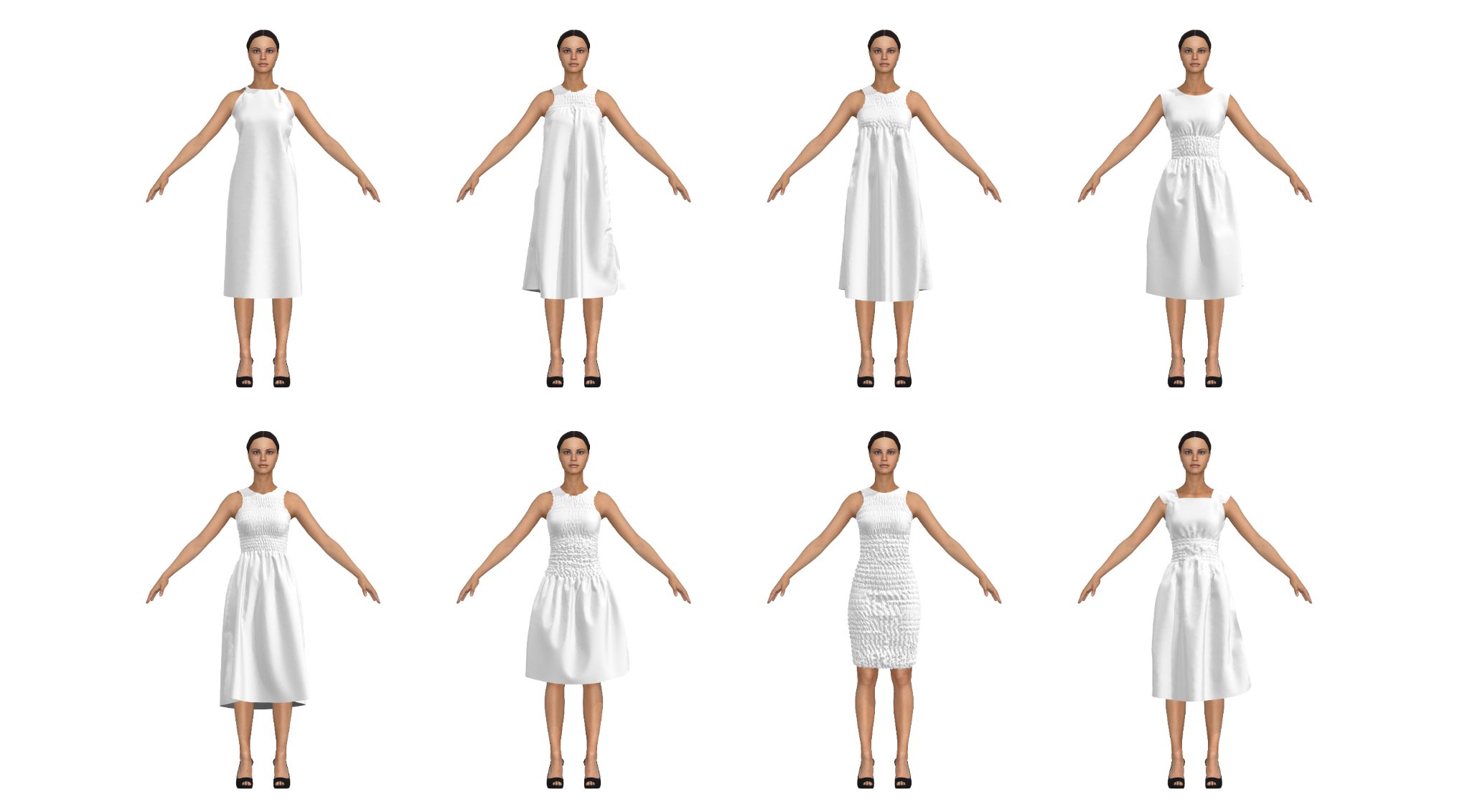

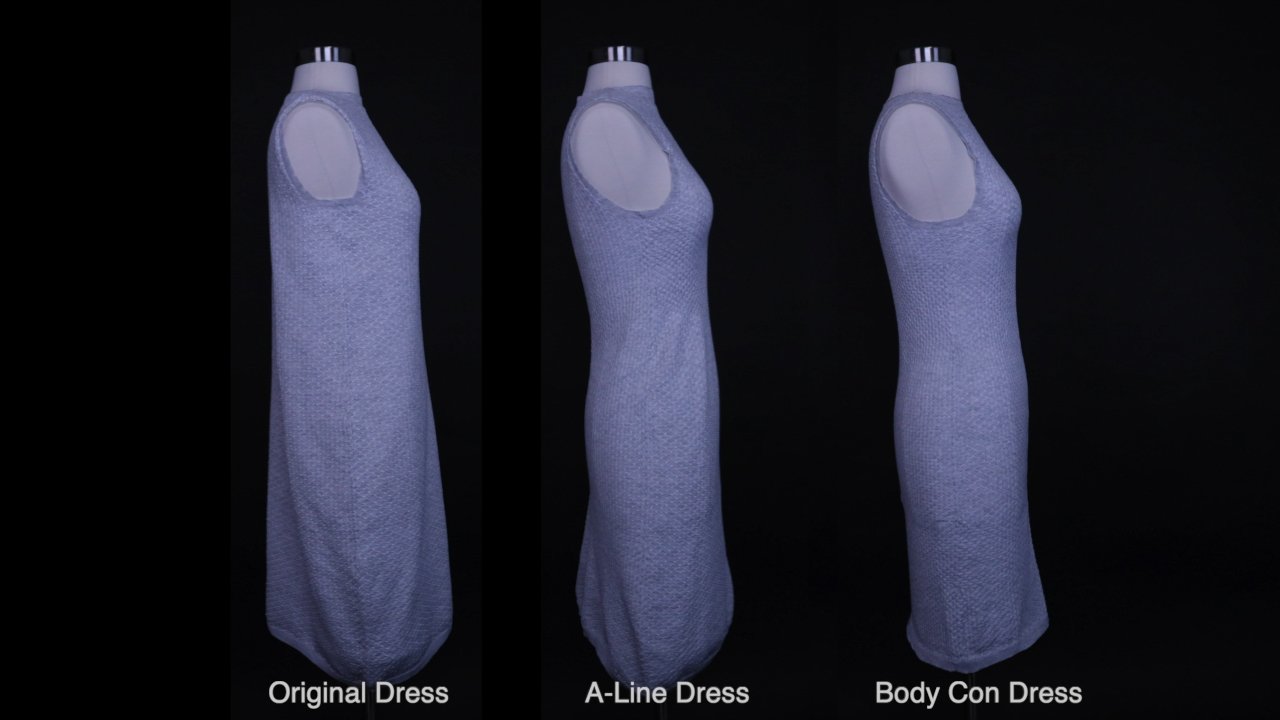

4D Knit Dress, combines several technologies – heat-activated yarns, computerized knitting and 6-axis robotic activation to create a garment that is sculpted to create a personalized fit or style. Heat-activated yarns are embedded within a unique knit structure to create controlled transformation, while maintaining softness, stretch and resilience. Using an efficient tubular knitting technique, a 6-axis robotic arm (commonly used in automotive manufacturing) heats specific areas to take-in – mimicking the design process of pinning & tucking used in traditional dress tailoring – transforming the dress in real-time to create a perfect fit or a unique look.